A two or three year boat building project invariably gets interrupted in all sorts of ways and the current detour is a desk I am working on. I was cutting the dovetails for the drawers, with my special dovetail routing system. It usually starts with cutting the tails on the bandsaw. The plywood guide has a thin wood piece attached to the bottom that slides in the slot on the metal saw top. It is marked with 8 degree pencil lines to lay the board for cutting at the correct angle.

After the outer cuts are made, a little more work is needed with the bandsaw or chisel, to remove the waste between tails. Then, it gets clamped to the router jig for marking the pins with my trusty pocket knife.

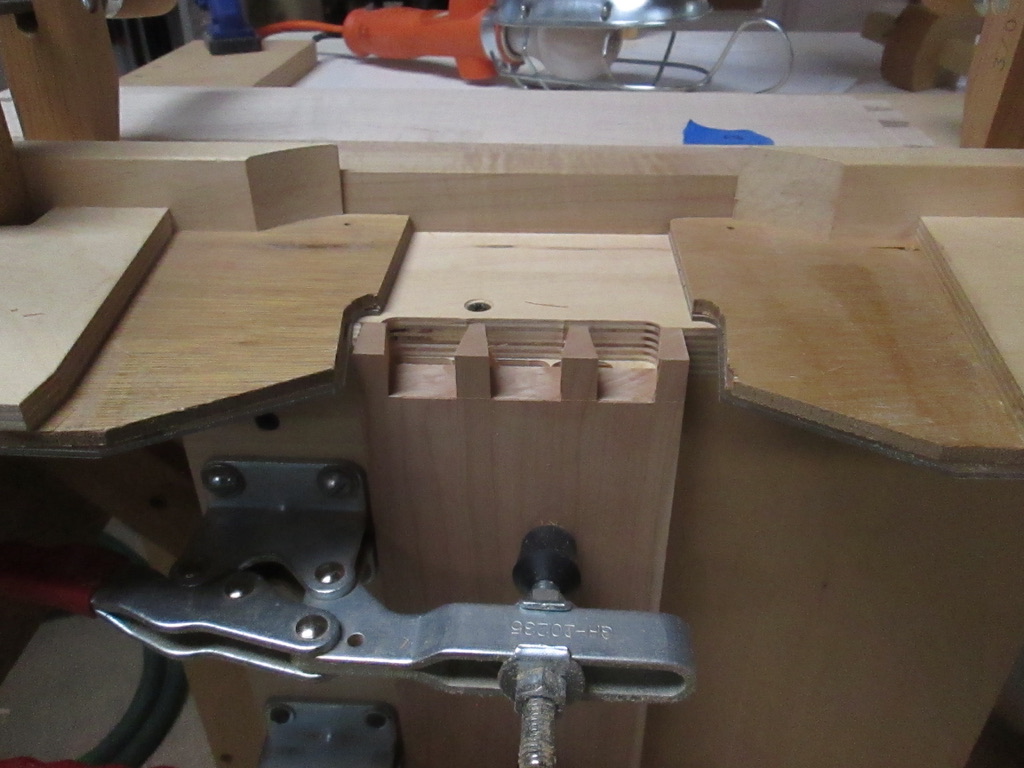

After that, it is moved to the front of the jig, and clamped flush with the top.

The sliding table sides are moved exactly to the pocket knife marks (not easy to see here) and clamped in place.

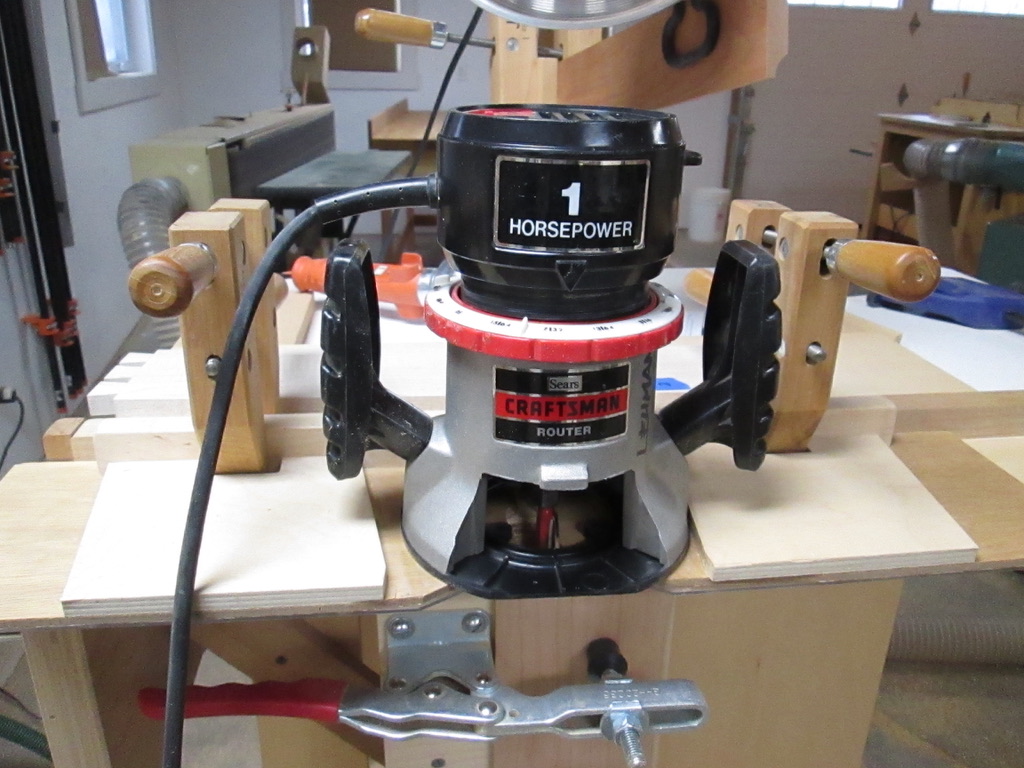

The router is then set to the correct height for the width of the drawer side, and it is ready to roll. Normally for through dovetails, I cut all the way to the back fence.

If all goes well, the router does a quick and accurate job of taking out waste.

Checking the fit should look like the example below, and quite frequently does.

When I want the dovetails not to be seen as on the front of some drawers (half-blind), I use a spacer against the back fence to stop it short. It was going well except for one cut, and I forgot to put in the spacer to limit the router travel. Of course, this was the last step in the drawer construction, and of course, it was the last drawer corner I was cutting.

Haste makes waste, and when I felt the router going all the way to the back of the jig, I knew I was in trouble. Sure enough, I routed right on through the drawer front, making the big hole below.

I considered starting over but didn’t have the right size wood, the time, or as I heard one college summer in construction, “It ain’t a church.” Angled or curved repairs are much easier than a square cross grain fix, so I had to look carefully for a scrap piece that had some end grain to match pretty well.

I bothered to fit the piece as well as I could to line up the grain. After gluing and sanding it flush, it disguised well enough not that I decided not to mention it to my “client,” my grandson. He had been helping build the desk for himself, but was not present at this step.

I rather doubt if he will notice the repair right away. But, some day when some random thing goes wrong for him, I will ask if he has noticed the mark on the drawer front.

Now, I wouldn’t trade the drawer for a perfect one. It becomes the enduring story of how life goes, when what was hoped for does not happen, and must be worked through with creativity and perseverance. It is a life lesson waiting to happen . . .