All boats have some curved surfaces, and the most beautiful have many curves, all hopefully contributing to a cohesive complete package. Some modern boats have curves in only one plane, and that makes construction easier. But traditional wood boats, and ones I wanted to pay respect to, have surfaces with curves both ways. That makes hills or valleys and it gets complicated.

Below is the boat at completion of setting the long trim moldings that define the cockpit, and end at the stern. Now is the time to figure out the shape of the stern.

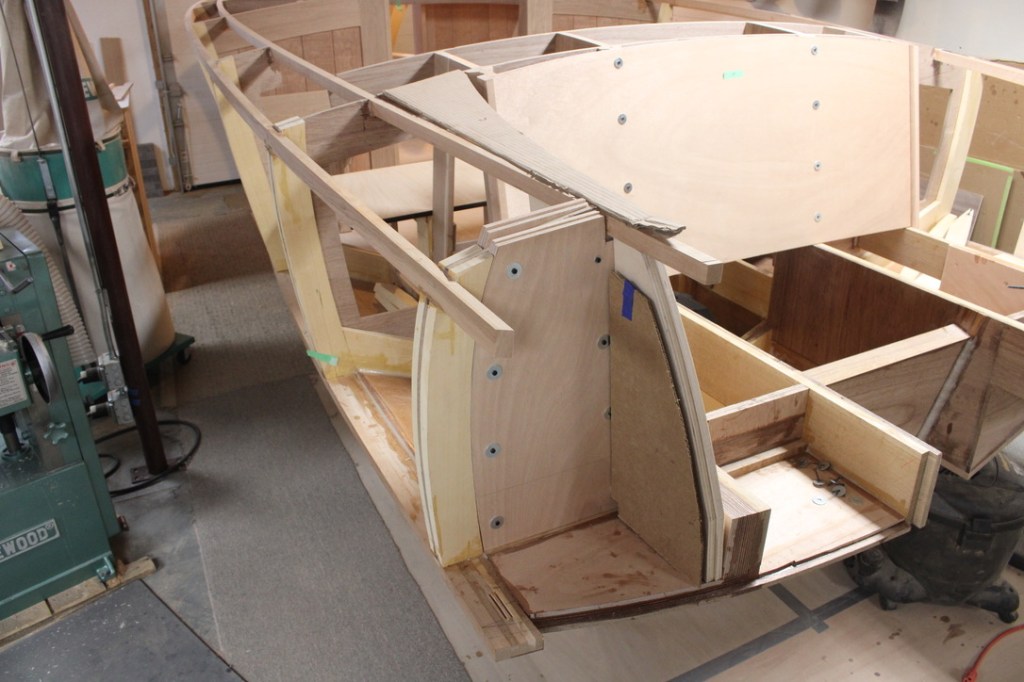

At the back on the outside, there is the inward curve or tumblehome, that adds width and buoyancy to the back, and just looks cool. And since an outboard motor on a wood boat can look out of place, the sides were extended to enclose it a bit.

New shapes usually begin in cardboard, then on to plywood if I need a rigid pattern. The piece of cardboard laying on top is to visualize how the wall of the engine well might look, and of course, it just came out curved as well.

That makes sense considering the back wall is also curved.

Then, to finish the double curve on the stern sides, internal runners were made for the first layer of tongue and groove shell to follow the side curve.

Eventually, it will be contoured, with both directions relating to both curves at the corner. The complication may be forgotten, and a complimentary form left standing. Beauty has a price.

Having toured many of today’s fiberglass boat factories (EbbTide, Mastercraft, Monterey, Chris Craft, etc) and having seen how they create a “plug” (reverse of a mold) that is then used to produce a fiberglass hull, makes me really appreciate the intricate thinking, planning, measuring and modeling that you are doing in creating LehmanCraft II

To create the “plug”, they simply begin with a very large block of styofoam and carve it down into the shape that they desire in the end product, compound curves and all. They have great flexibility and even have an automated process that replicates the design of one side of the hull to create the other side. What takes you many hours of intense work is now done by relatively unskilled laborers. But, they don’t put any love into their product, nor will they ever invite me to ride in their boat, as you might someday!

Great job, Dave!